Good day Jonno

We are a leading alternative building technology (ABT) company that enables people to construct houses using soil and cement, through an interlocking block system and no mortar.

We are looking for an architect who could design a number of environmentally friendly housing options of 40m², 60m² and 80m², with the option of additions but staying true to the African earthy look and feel.

Please review our website and inform me if this is something that you would be interested in doing.

Best regards

Dionne

Dear Dionne

Thank you for inviting me to get involved in this important modern-day requirement. Environmentally friendly homes have long been on my mind and I welcome the opportunity to add my contribution.

The following is a building concept that is not entirely new; it is based on the corbelled building principle of the early trekkers into the semi-desert areas of the Cape’s West Coast. The homes were built using rockwork and cob (mud) only – cement was unavailable then. Corbelled buildings and arches have a long history: they were built by Europeans and Asians three to four thousand years ago.

The homes were built using rockwork and cob (mud) only – cement was unavailable then. Corbelled buildings and arches have a long history: they were built by Europeans and Asians three to four thousand years ago.

What is new about the concept detailed here is the use of cement, waste products and structural technology input. Waste products include car tyres, plastic bottles, concrete and brick rubble, plastic wrapping sheeting, metal and timber cuts. Today, one can build a home with all these discards combined with cement and river sand.

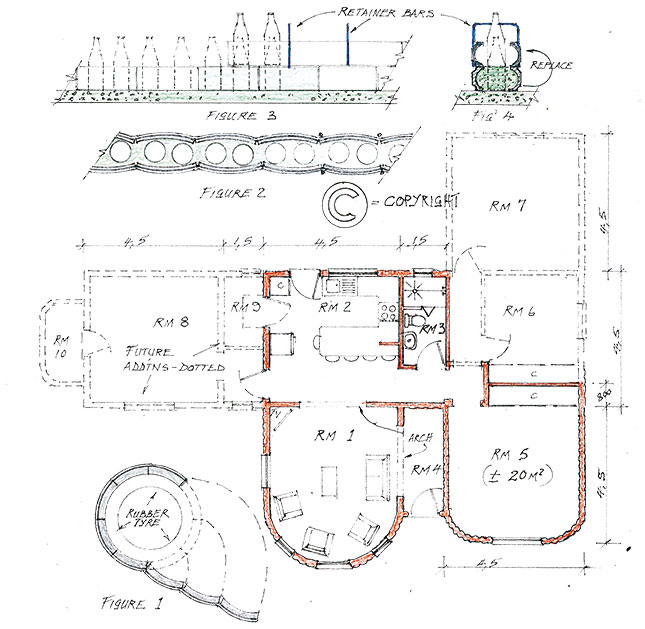

This structure can be used to create a home that will last a thousand years or more. Unique to the building application is the use of discarded tyres, thousands of which are generated annually. Figure 1 shows a tyre that has the tread trimmed away from the side-walls. This

This remaining tread, with a small rim of the side walls, is then divided into eight segments by cutting both side-walls back to the edge of the inner tread. Doing this allows the complete tyre to be opened up into a long, straight line.

In Figure 2 is the plan view of the extended sections of two tyres that will be used as the mouldings for casting a concrete wall in situ. Shown too are waste plastic bottles inserted to create air pockets in the wall; this saves concrete mix and assists thermal control.

Figures 3 & 4 show metal rods, bent to a U-shape to retain the tyre sections in position.

Shown in the house-plan layout is a 4,5m x 4,5m square room. As can be seen, any wall shape, even a complete rondavel, can be used.

Critical to the design is the converging of the roof over the walls, whether they are square or rounded, so that it is self-retaining, similar to the corbelled roofs of years gone by.

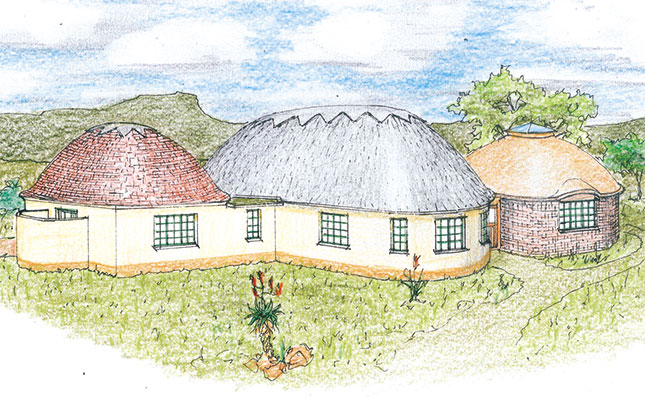

It is important that the construction of the roof is certified by a professional structural engineer. The 4,5m x 4,5m rooms can be built individually as time and finances permit. Shown in the perspective is a mixed version of the various shapes and styles that can be contrived with a bit of imagination. The walls can be smooth-plastered or have a moulded tyre finish.

The 1,5m wide gaps between the 4,5m² x 4,5m² rooms can be wider and serve as additional space. Any other regular roof can be constructed over the walls below.

This design basically reintroduces a proven technology, but with an environmentally friendly backbone.

Give me a call and let’s see what we can put together.

Kind regards

Jonno