Photo: Glenneis Kriel

Longevity. Production. Fertility. These are the cornerstones of production at Fair Cape’s dairy farms, Welgegund and Three Sisters, near Durbanville in the Western Cape. The most important of these is longevity, according to Johannes Loubser, director of farming operations.

Loubser knows what he is talking about. He won the ARC National Master Dairyman of the Year Award in 2015, 2018, 2020 and 2022, as well as the Western Cape’s Master Dairy Farmer of the Year in 2012.

At the time of writing, the dairy had about 2 500 cows in milk, consisting of approximately 2 120 Holsteins, 210 Ayrshires for their branded programme at Woolworths, and 170 Jerseys to boost milk solids.

Fair Cape also has 2 500ha of land under a rotation of wheat, canola and oats, as well as 350ha of lucerne under irrigation.

Production

A lot has changed since Loubser’s father, Eduard, started the dairy operation in 1955 with a herd of 64 Friesland cows. Loubser and his four brothers launched the Fair Cape brand shortly after deregulation in 1995.

“Milk prices were low, so we realised we had to find a way to add value to the milk. The farm initially supplied the old 7-Eleven shops with 1ℓ milk sachets.”

Since then, Fair Cape has extended its sales to all the major retailers, and its product offering has grown to include UHT milk, flavoured milk, yoghurt, juice, dairy desserts and butter.

“It has taken a lot of sweat, blood and risks, but we have managed, over time, to establish ourselves as a strong and sought-after brand,” says Loubser.

Production has grown from a few thousand litres to over 95 000ℓ/day, while yield per cow has increased from an average of 22ℓ/day to roughly 40ℓ/day for the Holsteins.

The Ayrshires were introduced to the farm a little over a decade ago and yield about 30ℓ/cow/day, whereas the Jerseys on average produce 28ℓ/cow day. The cows are milked three times a day.

In 2012, Fair Cape boasted the first cow in South Africa to produce more than 100ℓ/day, with three of their Holsteins accomplishing this feat after that.

“You get these extraordinary cows every once in a while. Their high milk yields does not affect their longevity or health negatively, because they have access to sufficient rations to help maintain their condition,” says Loubser.

He points out that the feeding of dairy cows has become “really scientific” over the past two decades, with dairy farmers these days having easy access to feed experts to guide the formulation of rations, help identify feeding problems, prevent nutritional imbalances, and keep cows in the best possible condition.

“The feeding of dairy cattle has become extremely precise, which helps to reduce wastage while allowing farmers to maximise the productive potential of their cows. To keep things simple, however, high performers at Fair Cape get the same rations as average or lower performers in the same productive cycle. The higher performers simply eat more to satisfy their productive needs,” Loubser explains.

While inter-calving period and yield per cow will always be important, Loubser points out that the focus has shifted to production per lifetime, in other words, the volume of milk produced by a cow over her life.

“It is great to have a cow with an above-average yield, but it means nothing if she cannot sustain it,” he explains.

In 2006, Fair Cape had its first cow that produced more than 100 000ℓ of milk over her lifetime. That number has since increased to 64.

Cow comfort

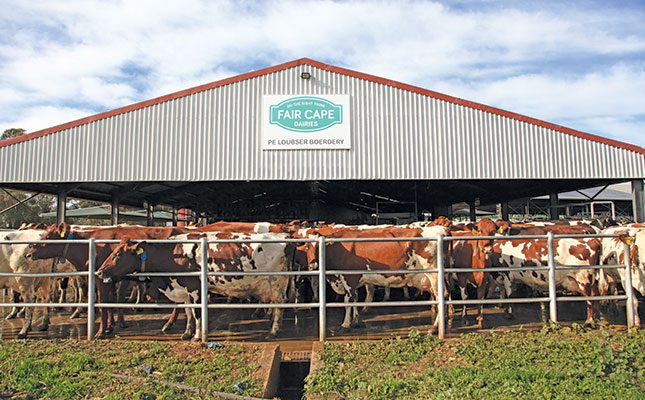

Loubser identifies an increased focus on cow comfort and welfare through the introduction of cow housing as another major contributor to yield improvements.

Introducing cow houses to the farm is a huge expense, so Loubser went to various overseas countries around 2005 to look at different milking systems.

He especially liked what he saw in Israel, linked to the fact that Israel’s climatic conditions are similar to that of the Swartland. This helped him decide to employ an Israeli dairy specialist to help with the design of their system.

The specialist drew up plans for cow houses, going into detail on the layout, orientation, size of cubicles, feed and walking space, and effluent management.

The plans also included the design that allowed the switch from Fair Cape’s old herringbone milking parlour to a 64-cow rotary system.

“The cow housing and milking parlour were two of the best investments we had ever made,” he says.

He explains that cow housing helps greatly to improve cow comfort, and in effect longevity and health, by sheltering cows against the elements: wind and cold in winter, and heat in summer. Today, all the commercial dairies in the Swartland make use of cow housing.

While there has been a lot of debate over the years about the best bedding to use in these systems, Fair Cape over time settled on compost, consisting of decomposed cow manure.

Loubser explains that it is much cheaper and more practical than having to transport sand to the farm. The farm also uses effluent to fertilise lands under wheat production.

Good stockmanship

Along with this, there has been a greater focus on good stockmanship and the production of tamer cows that are easier to handle.

Loubser says dairyman Anton Starke used to be one of his great inspirations when he was still a child.

“We visited Anton’s dairy one day and saw the most peculiar thing. His cows were so tame that each of them went over to him for some attention after being milked. Their tameness was a direct result of the fact that he was constantly with the animals, so they were used to him, and the gentle way in which he worked with them.”

Loubser admits that dairy herds have grown too large these days to pay individual attention to cows, but he feels that farmers still have to make regular time to walk among the cows to see for themselves that everything is okay.

Loubser adds that giving calves a lot of attention during the first couple of months after birth helps them to be used to people when they are mature.

Cow health

The arrival of new and improved digital technologies brought great improvements.

“I remember clearly how I complained about the fact that you could not see what was happening with individual cows around 2002. A while later, I heard of technology that monitored the movement of cows to help identify when they were in heat. Today this technology is so sophisticated that it also allows farmers to identify cows that are potentially ill,” says Loubser.

The technology opened the doors to artificial insemination and better fertility, reproduction, calving and cow health management.

“Being able to treat sick cows early is a major advantage as it means the treatment might be more effective and the cow might suffer less stress, which can negatively affect milk production, fertility and longevity.”

Four years ago, Loubser started using genomic testing on the herd to accelerate genetic progress and take the guesswork out of the breeding and selection of animals.

He explains that young calves are tested for traits related to milk production, longevity and health to help him identify animals that should be incorporated into the herd. A high somatic cell count, for instance, indicates a susceptibility to mastitis.

Along with this, sexed semen is used on the genetically superior animals in the herd to accelerate genetic progress by ensuring these animals only produce female offspring.

Poorer performers are inseminated with Angus genetics and their offspring are sold for almost three times more than a dairy calf would fetch to the beef market.

Industry woes

Loubser identifies rising input costs and particularly load-shedding as major industry challenges.

“Input costs have skyrocketed over the past few years, whereas milk prices have moved sideways for the past nine years. There used to be over 20 000 dairy farmers in the country a little more than a decade ago, of which about only a thousand have survived financially.”

Loubser is concerned about highly skilled farmers who are still leaving the industry.

“Up until now, the local industry has been able to supply the local demand, but I don’t know for how much longer. The farm-gate milk price for producers that has increased over the past year has helped to counter escalating input costs, but it is not enough,” he says.

Fair Cape installed a 1MW solar plant between 2020 and 2021, which has helped to reduce the business’s carbon footprint and energy usage. Loubser points out that, unfortunately, this helps only during the day and when there is no load-shedding.

To further reduce their dependence on Eskom and reduce the impact of load-shedding, the business is investigating other alternate energy supply sources, like biodigestors and wind turbines.

Email Johannes Loubser at [email protected].