Farmers are increasingly turning to mechanisation to improve productivity and save on labour, and the dairy industry is one of the most highly mechanised in the sector. Now an innovative dairy farmer has come up with a design for a calf feeder that could help dairy farmers and improve conditions for calves.

Machine design

Gawie Willemse of Weltevrede farm in Heidelberg milks 110 Jersey cows twice a day and has a yield of between 16l and 20l of milk per cow per day. A planned upgrade to a computerised herringbone system proved to be less stressful to the cows, reduced milking time and saved money on labour. But there were still calves to feed, and with young animals being fed by hand, the system was highly labour-intensive.

“The calf feeding was done manually and often lacked consistency,” says Willemse. “Calves would not all receive the same amount of milk and it was difficult to keep the milk at a constant temperature. From time to time, we’d lose a calf because our feeding regime was not effective.” Willemse, who has always had an interest in automation, started thinking of ways to improve the calf feeding system on his farm.

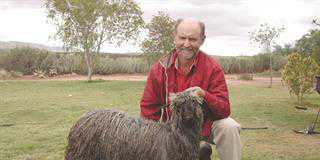

Gawie Willemse (left) and his son Cobus are gratified by the success of the calf feeder.

After a time, a design for a piece of equipment that could feed calves mechanically and replace the manual system started to emerge. In April, Willemse built a prototype. “I had a computerised electronic system designed according to my specification that could run the device automatically,” he explains. “I kept the structure simple so the costs of building the machine were as low as possible. A simple design also means straightforward maintenance.”

After a trial period, Willemse fine-tuned his design and built a second machine that functioned exactly as he envisaged.

“When I chose the building materials, I used parts that are freely available so that it would be easy to build more of them. Now that the design has been finalised, I should be able to build one of these machines, from scratch, in about three weeks,” he says.

The calf feeder has gates in front and behind, a holding area where the calf stands while drinking, a milk tank, pipes carrying the milk from the tank to the calf, a water bucket with heated water to warm milk before drinking, and an electronic control panel for the feeding cycle. At a cost of about R30 000, one machine is sufficient for 30 to 35 calves.

Effective feeding

Calves can drink from the machine when they are a week old. Because using the machine makes feeding more effective and consistent, calves grow out faster and can be weaned at two months. In the past, Willemse found that he had to wait until the calves were at least three months old before weaning them. He has also found that the calves drink more milk with the machine than with hand-rearing, which also contributes to their faster growth.

“We fed calves at least 3l of milk per day. With this device calves have ad lib access to the milk and we find that they drink about 4,5l to 5l per day. The machine dispenses 500ml at a time,” he explains. The machine is thoroughly cleaned every morning before the first feeding. For more information about the calf feeding machine, phone

Gawie Willemse on 082 787 5680 or email [email protected].