Photo: Supplied

Subsurface irrigation has been widely adopted in the production of highly mechanised crops, such as sugar cane and lucerne, because it helps to improve labour efficiencies and reduce damage to irrigation infrastructure.

Added bonuses are that water is delivered directly into the root zone, reducing water losses caused by evaporation in overhead irrigation, and farmers can apply fertiliser via irrigation, which reduces labour costs and improves fertiliser efficiency.

Hardly any fruit and grape farmers, however, are using subsurface irrigation in their orchards in South Africa. In ‘The pros and cons of subsurface irrigation’, which featured in Farmer’s Weekly on 18 August 2018, both Pieter Fouché, viticulturist of Graham Beck Wine Estate near Robertson in the Western Cape, and Dr Philip Myburgh, a retired researcher of the Agricultural Research Centre Nietvoorbij, advised against the use of subsurface irrigation.

The challenges

Why? Fouché said that they planted 6ha of Chardonnay wine grapes under subsurface irrigation in 2004 to improve their water use efficiency. They got the idea to use subsurface irrigation during a visit to the Margaret River wine region of Australia, where farmers claimed it reduced their water usage by roughly 30%.

Fouché during the interview back then, and now again, confirmed that Graham Beck never saved more than 10% water per season on the vineyards where they installed subsurface irrigation. He blamed this on Robertson’s soils being much more diverse than Margaret Valley’s deep alluvial soils, and the difficulties in managing these variations.

Fouché said they installed overhead irrigation in these vineyards last year because the roots of the vines under subsurface irrigation started growing to the middle of the rows. Driving with equipment inside the rows caused compaction, which in turn resulted in the roots breaking.

Agricultural Research Centre trials done from 1999 to 2004 with subsurface irrigation on alluvial soils, at different depths, on Thomson Seedless vineyards near Upington did not find subsurface irrigation more efficient than surface drip irrigation.

Myburgh back then explained that this was because subsurface irrigation still found its way to the soil surface thanks to capillary action in the soil, from where the water evaporates.

Fouché said that a 10% reduction in water usage might become more attractive in future,

as water became scarcer and more expensive, but that there were various reasons why he would think twice before using subsurface irrigation again.

Firstly, he said, because it worked out substantially more expensive than overhead irrigation and required additional equipment, such as manifolds and valves to flush the system, that further drove up costs.

Young vines also needed surface irrigation as their roots were not well developed enough to reach the water supplied via subsurface irrigation. It took five years before he felt comfortable enough to remove the surface irrigation lines.

Farmers also needed to be more vigilant to detect problems and blockages, since the physical delivery of water cannot be seen with subsurface irrigation, he said.

New development

David Wesson and Richard Clarke of DNA Technologies believe their patents will overcome these challenges and revolutionise irrigation in the fruit and grape industries.

“In the past, people in South Africa took a standard dripper pipe, dug a channel, dropped the pipe into the channel and planted their vines and so forth on top of the now filled-in channel and referred to it as a subsurface irrigation system.

This was doomed to fail before they even turned the water on, because standard dripper pipping is not developed for this, and the system would be prone to blockages,” Clarke says.

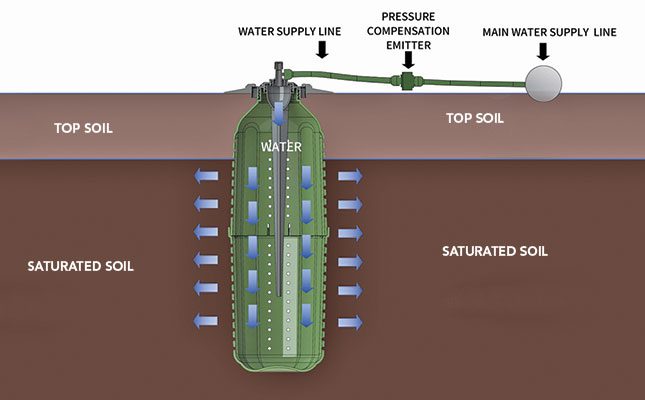

He adds that DNA Tech-nologies patents by contrast are specifically developed for subsurface irrigation. The patent consists of a tube-like dispenser with a dripper on top, of which only the dispenser pod is placed in a hole that is drilled into the soil.

The pod should be placed roughly 300mm from a tree, with one being sufficient when trees are young, and two required when trees are older depending on the type of fruit and climatic factors.

The emitter at the top of the dispenser, which is above the soil, is attached to a feeder line that is connected to the main irrigation lines. These might be kept on the ground, suspended or buried.

Clarke says this makes their patents cheaper and less labour-intensive to install than traditional subsurface and subterranean systems, and allows farmers to switch to DNA Irrigation’s system in existing orchards without having to change existing piping. The pods are easy to remove if farmers want to use them in other orchards.

Another advantage is that it is as easy to see blockages as it is with surface irrigation.

“Blockages are near-impossible thanks to the design of the system. However, if blockages should occur, water will start to run out of the nipple that connects the dispenser with the feeder line and allows oxygen into the system,” Clarke explains.

The dispenser is made from reconstituted UV-resistant polypropylene plastic, which has an expected lifespan of about 25 years with reasonable use. It is also completely modular, allowing farmers to replace broken parts easily.

The first patent was developed for soil in general, whereas the second, which DNA Irrigation refers to as a deep root soil amendment irrigation system, was specifically developed for soil with a poor water holding capacity.

Water is delivered straight into the pods of both the original and deep root soil amendment systems, but the pod of the latter system is filled with a medium that has a good water holding capacity, such as vermiculite, to reduce the volume of run-off water.

The deep root soil amendment irrigation pod is 350mm long and 100mm wide, with a capacity to hold 3,5ℓ of material, whereas the pod of the first patent measures 130mm long and 45mm wide.

Clarke says it should not be a problem if the roots of the vines or trees grow into the pods, as it would not impact the water holding medium. The water holding medium can also be topped up, if needed, by merely screwing the top of the pod open and adding new material.

Clarke believes that the deep root water amendment system will allow farmers to plant trees and vines in areas where the poor water holding capacity of the soil once prevented this, and that the two systems can reduce evaporation.

This in turn could result in water savings of up to 40% while substantially reducing the energy costs associated with pumping irrigation water.

As with drip irrigation, fertiliser can be applied via subsurface irrigation. Clarke says that the advantage of their systems is that the fertiliser is placed deeper in the soil, near the roots, where it is needed, which he believes improves fertiliser use efficiency.

DNA Irrigation also released a patent for slow-release medicator. The medicator can be filled with nutrients or “medication” for the treatment of individual trees, removing the wastage associated with blanket fertiliser or pest treatments.

It is fitted to the main body of the subsurface and deep root water amendment systems of the trees that require treatment.

The medicator has two incoming water lines: one that feeds to the subsurface irrigator and another that feeds the medicator at a lower rate. The slow-released medicated water is mixed within the subsurface irrigator body prior to being disbursed to the root-bowl region.

The science

Clarke claims that subsurface irrigation with this type of technology has become widely adopted in fruit orchards, nut orchards and vineyards in the US.

He specifically referred to a video discussion with Doug Misantoni, director of Deep Root Revolution, and Jared Casey, the farm manager at Gerry Hudson Ranches.

The farm is situated in Reedley, California, which has a Mediterranean climate with dry, hot summers and mild wet winters. The region has an average annual rainfall of a little over 300mm/year.

Fourteen months after the system was installed on newly established citrus trees, the use of the subsurface irrigators resulted in the farm only having to irrigate the trees twice a week for two hours, whereas they had to apply water for 24 hours, twice a week, with surface drippers, according to Casey. The emitter delivery of both the systems is the same at 7,57ℓ/hour.

Evaluation of patents is needed for South African conditions

Clarke says their patents are similar to the system developed by Deep Root Revolution in the US, but adds that the estimate of the water and energy savings potential of their systems is more conservative.

While most of the feedback he referred to is anecdotal, and DNA Irrigation’s patents have not been evaluated scientifically under South African conditions, Clarke feels the information speaks for itself.

He added that companies that sold dripper-line systems for orchard and vineyards were unlikely to support the use of subsurface irrigation, as it was “a disruptive technology” that made inroads into their formally safe market.

“We would like to say that not all subsurface irrigation is successful, just as not all sprinkler and spray irrigation is successful because of design and other factors,” Clarke said.

DNA Irrigation is not planning on selling the technology itself but is looking for agribusinesses to take over the distribution. Clarke said they had had some fruitful meetings about this.

Email Richard Clarke at [email protected].