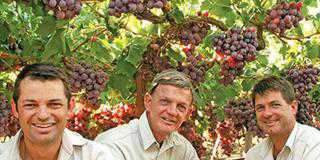

The Paarl area is not considered ideal for table grapes as they ripen at the same time as grapes from other countries, resulting in a market glut. Early ripening areas north of the Orange River and the late-ripening Hex River Valley are considered more practical. But Johann Britz of the farm Tweespruit near Paarl believes that with the right cultivar, good quality and size, this isn’t a problem. He managed to pack an average of 5 300 export cartons per hectare during the 2008 season.

“My father bought Tweespruit in the 1960s,” explains Johann. “The farm was sold in 1996, and we bought a table-grape farm in Trawal on the West Coast. My wife Janel and I farmed there until 2001, and then bought back Tweespruit.”

The farm had been badly neglected, giving the Britz family the opportunity to re-establish modern table-grape varieties and 3,5ha of citrus. In 2003, Johann established the locally developed, black pitted Ebony Star cultivar on a 1,2ha block, which won him the 2008 Berg Table Grape Competition.

Tweespruit is now under 20ha of 10 different table grape cultivars of which Crimson Seedless, Ebony Star, Autumn Royal, Midnight Beauty and Sundance Seedless are prominent. In 2009, Johann plans to establish 2ha of Starlight, a red, seedless variety and a further 2ha of Sundance Seedless. The Starlight cultivar will be harvested in the first and second week of the year, while Crimson is harvested by week 14. The citrus harvest starts in April.

Keeping things simple

The winning cultivar Ebony Star ripens during the sixth and seventh week with a reputation for weak colour development. “Due to the low elevation of Tweespruit we have cool evenings and the soils seem to enhance the cultivar’s colour development,” says Johann.

“I’m very particular about canopy foliage. While the grapes are green and hard we keep a dense canopy to avoid sunburn. As they soften, we reduce it for more light penetration to help colour development. We also apply an Ethopon spray of 80ml/â„“ of water when the colour change is at between 15% and 20%. This is later than industry standards, but we’re achieving good results.”

Johann insists on meticulous execution of each task during the production cycle. He says new products and production techniques tend to be expensive and often over-complicate things. His strategy enables operational costs at far below industry standard. Snail control is a case in point.

“We had a huge dune-snail problem two years ago when the pest got onto the farm in either lime or chaff brought from the West Coast,” remembers Johann. “Chemical control was harsh and expensive and manual removal was time consuming. Then I discovered ferocious Indian runner ducks and since then the snails are under control at minimum expense.”

Soil and moisture management

Before establishing new vines, Johann uses an excavator to sub-plough the soil to a depth of 1,2m, instead of the traditional 0,9m. This ensures good soil mixing and allows corrections. “Our soils are acidic at an average pH of 4,5,” explains Johann. “We apply lime and aim for a pH of 6,5. Although soil preparation is expensive at more than R20 000/ha, it’s worth it as it will determine the block’s productive potential for 20 to 25 years.”

Johann only sources plant material from registered growers. He uses Ramsey rootstock for vigorous growth and strong resistance to nematodes. Vines are established in 3m rows and plants are 1,8m apart in the rows. Irrigation is done with microjets twice a week. A long session allows deep penetration into the sandy soil and three days later a shorter session wets surface root hairs.

Moisture measurement is done with tension meters and holes are dug biweekly. “Experience and soil knowledge are vital to proper irrigation,” says Johann. He applies a granulated 10:1:5 fertiliser mix three times a year after budding, during set and after harvest. Once a year KNO3 is applied through the irrigation system. “I apply 20m3 of chicken manure per hectare in the winter months and chaff every second year. I use alternate cover crops of triticale and lupin one year and oats and grazing vetch the next.”

Vineyard management

Johann is specific about grape preparation as demonstrated by his treatment of the Ebony Star block. Winter pruning has shoots spaced at the length of pruning shears, leaving two growth nodes per short leader. Three weeks before foliation, a dormancy break spray is applied to ensure even foliation. When the shoots are between 10cm and 15cm long, suckering is done, leaving only two shoots.

When the bunches form, only one bunch per shoot is retained, as well as only the bunches closest to the old wood. Side shoots are removed and bunch carrying shoots, evenly placed, tied to a trellis. The vines aren’t girdled. Two weeks before flowering, a ureum spray of 1,5kg/100 of water is applied. If flowering coincides with cool weather, the spray is repeated, otherwise not.

The ureum spray causes looser bunch formation, saving labour as less bunch trimming is required later in the season. The bunches are trimmed to 8cm, with 12cm shoulders, resulting in uniformity of between 800g and 850g a bunch. “This is the ideal size preferred by the market,” explains Johann. “When all this is done, a selection team chooses the 20 best bunches per vine, removing everything else. This translates into 37 000 bunches per hectare, or between 6 500 and 7 000 cartons per hectare.”

Labour management

Johann employs 27 permanent workers, some of whom have a 20 to 30 year relationship with the Britz family. During peak season, 45 seasonal workers help out, 70% of them return to Tweespruit every year. “It helps if you don’t have to train new workers,” Johann points out. “I believe in good employee relations and treating my workers with respect. In return, they’re loyal to the farm and deliver work of a high standard.”

Contact Johann Britz on (021) 863 2489.

A considered strategy

On planting the Berg Table Grape Competition winner Ebony Star, instead of trying to get into production quickly, Johann pruned it back after the first winter. “This was to enhance the root system, giving it an extra season to develop before bearing fruit,” explains Johann. The vines were shaped the following summer and established on a gable-trellis system. Two single cordons were formed, with a split in-between to allow air and light into the canopy.

A crop was produced after the second year, and two years ago yield was 7 000 export cartons per hectare of XL grapes. The 2008 season saw 7 200 export boxes per hectare of XXL grapes. “Because Ebony Star is a pitted cultivar, it must have exceptional berry size, colour and taste to be chosen over a seedless variety,” explains Johann. “We’re fortunate to achieve all that and have a good market in the Far East.” His confidence is evident in planting another 1,2ha block of Ebony Star in 2008. “Establishing a winning block doesn’t happen overnight, it requires careful planning over several seasons,” says Johann.