The most important aspect of any farming enterprise is viability; this forms the foundation of sustainability. There is little sense, for example, in starting a hydroponic or greenhouse project if your primary motivation is to create jobs or improve the living conditions of local communities.

I have seen many enterprises fail due to poor planning and not focusing on the viability of the project right from the start, or even later, when in full production.

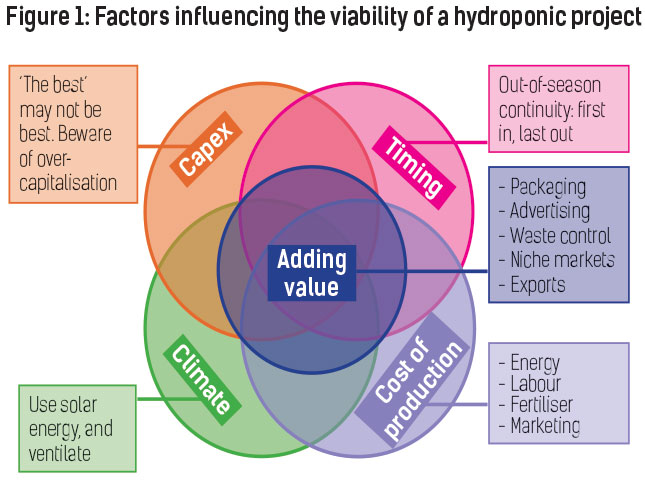

It also does not help to invest your capital in elaborate buildings, sophisticated greenhouses, smart hydroponic systems and full climate control without first considering the factors that could influence the overall viability of your enterprise (see Figure 1).

Make sure your timing is right!

Timing your production with care could help to ensure the viability of your undercover project. Study the market prices of the crop that you intend growing, and analyse trends.Spanish hydroponic growers time the production of melons and watermelons to arrive on the European markets early in the season.

Prices are then on average three to four times higher than later in the season when the markets are flooded with open-field crops grown in warmer weather. The same trend occurs in South Africa, with melons and watermelons being very expensive at the beginning of the season, before the bulk of these products become available at much lower prices.

All year round

It is also important to get your greenhouse and hydroponic system into full production immediately after installing the infrastructure, and keep it in full production for 12 months of the year. While acting as a mentor of a government-sponsored project in the Western Cape,

I discovered that new tunnels had stood empty for six months before the first crop was planted, and again from March until November before the second crop was planted.

Being out of production for 15 out of 18 months reduced the venture’s revenue potential by more than 80%.

Keep production costs down

It is relatively easy to install boilers or other heating equipment to warm up the internal temperature of a greenhouse in winter. However, in South Africa’s mild climate, it is worth looking at other low-cost alternatives that could provide similar results.

Solar energy, for example, has replaced costly boilers or other heating equipment in some greenhouses in far colder climates than ours (see photograph on the left). These systems are designed to collect and store solar energy from south-facing (northern hemisphere) transparent glazing during the day, while heat loss is prevented by an insulation blanket that is rolled down over the outside of the greenhouse during the night.

A significant portion of the solar energy is stored in the rear and side walls of the structure, from where it is radiated onto the plants at night to keep them warm.

Optimise capital expenditure

Greenhouse suppliers and growers throughout South Africa often ignore the benefits of using energy and rainwater available at no cost from nature, in favour of expensive industrial and other solutions.

For example, plastic tunnels can be cooled in summer with simple, cheap ridge ventilation openings that replace hot interior air with cooler ouside air, instead of expensive, energy-sapping fans.

Consider using wind, solar or underground energy sources instead of coal or other fossil fuels. Even the latent heat dissipated when water freezes could be used to prevent frost damage at minimal cost. Wine farmers in the northern US prevent frost damage in their vineyards by using pulsators and micro jets to spray minute quantities of water onto plants when the temperature drops below freezing.

The latent heat released during freezing is sufficient to keep the ambient temperature around the young plant shoots at about 0°C, even if the ambient temperature drops below -20°C.

Rainwater can be collected from greenhouses and other structures to supplement or even replace borehole water, or improve the quality of brackish water. Saving the rainwater in a shallow surface dam, lined with butyl rubber or a thick sheet of polyethylene to prevent seepage, requires considerably less energy than pumping it from a deep borehole, or over long distances from other sources.

An additional benefit is that rainwater quality is also the best available.

Alternative heating arrangements

Consider alternative solutions for supplying heat to plants to optimise growth and yield in winter. For example, it makes little sense to heat a greenhouse at night when there is no light for photosynthesis. Plant respiration is related to the prevailing temperature, therefore a higher night-time temperature results in a higher respiration rate, and some of the carbohydrates generated through photosynthesis during the day are broken down to produce carbon dioxide, a by-product of respiration.

Many experiments have been conducted in which the greenhouse temperature was allowed to drop at night, and the result was increased production with large cost saving in a broad spectrum of crops.

In addition, great savings and yield increases of up to 40% and more are possible if root zone warming is used instead of heating the entire greenhouse interior, which requires much more energy.

All these aspects will be discussed in greater detail in upcoming articles.

Email Prof Gert Venter at [email protected].

This article was originally published in the 13 January issue of Farmer’s Weekly.