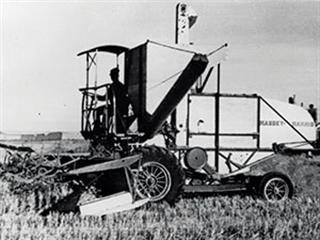

Introduced in 1938, the MH-20 gave us the term ‘combine harvester’ and pioneered a harvesting revolution. For the first time, the tractor was separated from a trailed reaper machine, thereby providing farmers who had to harvest large areas with huge gains in productivity and performance. There had been previous attempts to develop self-propelled combines, but none had been successful.

By contrast, the new Massey-Harris (as Massey Ferguson was known back then) harvester was an immediate success, especially among large grain producers. One reason the MH-20 succeeded where others failed was the skills of Australian-born design project leader Tom Carroll. He and his team started work at Massey-Harris’ engineering centre in Canada in 1936. Within two years, eight pre-production prototypes were delivered to farms in Argentina for field testing. Feedback was so positive that production was authorised immediately and the first of the revolutionary new combines was delivered early in 1939.

Tom Carroll on his retirement in 1961.

Carroll designed the new harvester as a high-output machine for large-area growers. It was equipped with a 4,9m header, which was wide by 1930s standards. The layout of the MH-20 was similar to that of a modern combine, with the header at the front, where it could open up a land without the wheels damaging crops – a problem of a trailed combine. The driving position was above the centre of the header with an excellent view of the cutting action.

The steering wheels at the rear delivered better manoeuvrability than a tractor-drawn combine. Carroll was awarded

a gold medal in 1958 by the American Society of Agricultural Engineers in recognition of his contribution to combine harvester development. The development of the self-propelled combine continued throughout the 1940s and 1950s with the MH726 being the forerunner of a range of successful Massey-Harris and, subsequently, Massey Ferguson models manufactured in the UK.

One of the first models to appear under the new Massey Ferguson name was the MF35 in North America – a small, low-priced machine for small- to medium-size farms. By the mid-1960s, following the introduction of the new MF300, MF400 and MF500 models, Massey Ferguson had claimed 18% of the worldwide market for combines.

The next model

With demand for the MH-20 at a high, Massey-Harris immediately began working on a smaller, lighter, more affordable combine. Sales of the MH-20 reached an impressive 925 machines in two years, but when the new MH-21 combine (above) arrived in 1941 with its 3,7m header, it created a huge demand, with annual production peaking at 10 000-plus in 1949.

During the Second World War, the ‘Harvesting Brigade’ of MH- 21s worked from the southern states in the US, following the ripening harvest north. In the process, more than 400 000ha was harvested in one year. With the MH-20 and MH-21 combines, Massey-Harris achieved an important breakthrough in harvesting, which other combine manufacturers were forced to follow.

Cool cab

A major development in combines was the addition of an enclosed cab for driver comfort. The first MF combine to boast a factory-fitted cab was the US-built MF750/MF760 in the early 1970s. Integral cabs appeared on MF European models in the early 1980s. The Skyline cab, introduced at this year’s SIMA Show, is a newly designed structure throughout, from the steps on the exterior to the floor mat.

Operators enjoy easier control and greater comfort than ever. Fully automatic climate control air-conditioning is standard, for example. The windscreen is particularly large and curves at the edges to provide a clear view of the widest headers. Insulation throughout the cab helps to seal out noise and dust and allows the operator to work in quiet and comfort. There are two seats fitted as standard: an air-suspended operator’s seat and a comfortable instructor seat fitted above the cooler and storage box.

The steering column is fully adjustable to suit all operator shapes and sizes and its narrow dimensions help to provide an obstructed view of the header.