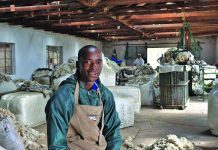

Photo: Denene Erasmus

Jan and Dries Wiese, successful Karoo sheep farmers, added a new dimension to their operation when they started making goat’s milk cheese.

“We’ve always had goats around. When we were children our grandad gave us each a goat to use as foster mothers for rearing hanslammers,” says Jan.

“Goats are intelligent and calm, less skittish than sheep, and one goat can foster six lambs,” adds Dries.

The power of one

Over the years goat numbers gradually increased, but the goats weren’t an income producing part of the farming operation.

The brothers inherited seperate farms, Kasteel and Biesiespoort from their father (Hentie Wiese) but, in 2010, they decided to amalgamate the farms into the Wiese Business Trust for economy of scale.

READ: Better milk, better cheese from veld-reared goats

“It makes sense, the benefits are substantial,” says Dries. “We have better buying and negotiating power.”

“Running the business off a secure base helps ensure a better future for our children, the farm workers and their children,” explains Jan.

Farmed as single units, the farms did not have the financial capacity to commit capital to high cost infrastructure such as a farm school, milking plant or cheese processing facility.

After they merged the two operations these investments were within their reach. Since joining forces, they have also established an SA Saddle Horse stud.

“By the time we decided to amalgamate, we had so many goats between us that we were faced with a choice – sell the goats or keep them and integrate them into the business in a profitable way,” says Jan.

Market research revealed a growing demand for goat’s milk cheese and other goat’s milk products in South Africa, so the Wieses decided to take a leap and set up a cheese factory to process their milk.

They built the factory on Biesiespoort farm early in 2011 and by August had produced the first goat’s milk cheese in their Goat’s Milk Products line.

Milking and breeding goats

“When we started we milked only Saanen goats, but we have since bought in a few Alpines and Toggenburg goats,” says Jan.

READ: Know your goat breeds: The Toggenburg

He explains that the Saanen goats produce a greater volume of milk, something like Holstein cows in the dairy industry, but the milk of the Alpine and Toggenburg goats has a higher butterfat content, akin to that of the Jersey cow.

The Alpine and Saanen goats are generally large and big-boned, while the Toggenburgs are slender and of a lighter build.

In their first lactation, the goats give only about 1,7l of milk a day, but mature goats can milk up to 4l a day.

According to Dries they currently have about 120 milk goats with 75 in milk, producing an average 2,5l to 3l of milk a day. The 45 remaining goats are doe kids coming up for breeding.

Some of the less productive ewes are used as surrogate mothers, as the ewes return to the dairy for milking three days after kidding.

“Milk goats are seasonal breeders, meaning that they will conceive, if mated, between January and May, after which the breeding season is over. Goats have 17-day cycles and a gestation period of about 150 days.

“We put the rams in with the ewes from mid-February for 34 days, which covers two cycles,” explains Jan.

The Wieses do not artificially inseminate as they feel they do not need to. Their ewes have no conception or lambing problems.

At 12 months, young females go through a selection process and are rated in terms of fertility and conformation.

According to Jan they look at a number of aspects including udder attachment, teat placement and shape, feminine traits and refinement in bone and body.

The Wieses breed their own rams, but also buy in from other flocks to introduce hybrid vigour and keep the stock genetically robust.

“Rams are selected on the basis of their parentage; we want them to come from highly productive ewes and rams,” Jan says.

Rams that are not selected to form part of the breeding programme are castrated and marketed at two months.

“We want productive goats with a uniform build. We would like to grow the flock to about

1 000 milk goats, which will take us to maximum capacity as far as the factory is concerned,” says Jan.

From parlour to factory

An old stable has been converted into an automatic, nine-point swing-over milking parlour. Dries says that with 20 animals aside, one line can be milked in about 10 minutes.

For the first few months Jan made the goat’s milk cheese, but found this left him with too little time to attend to other farming, so the brothers appointed veteran cheese maker, Wicus van der Merwe to help them.

According to Wicus the three most important ingredients needed to make good goat’s milk cheese are good quality milk, a good active culture and excellent hygiene in the dairy and the cheese factory.

READ: Putting goat milk cheese on the map, one award at a time

Strict hygiene control parameters are in place and standard dairy washdown procedure is practised. Milk is pumped via pipeline from the dairy to the factory which minimises contamination.

From May to July the ewes are dried off two months prior to giving birth. Routine maintenance is carried out on the milking plant and the factory during this time. Sales do not come to a standstill however, as advance planning ensures that stock is available to supply the market.

Goats are milked twice a day but cheese is made only twice a week on Mondays and Thursdays. The milk passes from the pipeline through a filter to the milk tank in the factory.

“In the tank the milk is cooled to 2°C and stored there until we make the cheese,” says Wicus.

From the tank, milk goes through the pasteuriser where it is heated to 73°C for 15 seconds, cooling through a plate heat exchanger to about 10°C to 15°C.

Once in the cheese vat, milk is heated to 31°C before the cheese making process starts.

“This is the setting temperature,” says Wicus.

The main production lines are a Cheddar type cheese and goat milk feta, but Wicus also makes halloumi and ricotta cheese.

When asked about the shelf life of their cheeses Wicus declares somewhat indignantly that goat’s milk cheese does not have a shelf life.

“Like wine, it only gets better as it matures.”

Growing the goat’s milk cheese business

“I think any business takes three years to get on its feet. We have been at this for about a year. The next two years will determine what type of cheese we should be making, where our market is and how big it is,” says Jan.

The Wieses transport their product to various outlets on the Cape south coast from Knysna to Cape Town. They have also recently approached the Checkers group in Gauteng.

“The local market is just too small,” says Dries.

Optimistic about the future, Jan says they process 1 000l to produce between 80kg and 110kg of cheese a week, but aim to grow to a size that could supply enough milk for the factory to run at full capacity – processing about 5 000l a week.

Wicus is just as upbeat about goat milk products in South Africa and his parting advice to sceptics is simple.

“Forget your prejudices about goat milk products, be brave and try something new, you won’t be sorry.”

Fore more information, phone Karoo Goat’s Milk Products’ head of marketing, Karike Scheeres, on 082 382 7094 or email her at [email protected].

This article was originally published in the 18 May 2012 issue of Farmers Weekly.