It all began with heidi. ten years ago the elderly Swiss couple Stephan and Mia Loringett kept a Saanen goat called Heidi as a novel lawn mower on their farm Sangwee near Skeerpoort in North West. But when Stephan, a chef, started experimenting with goat’s milk products, it wasn’t long before Heidi was joined by 20 more goats. In December last year, brothersin- law François de Chalain and Jean Vos bought the business. “I farm with organic vegetables, and wanted a sideline business that would provide me with manure,” says François.

With the goat’s milk Jean produces yoghurt, cottage cheese, feta cheese, haloumi, ricotta and kefir, a drink similar to maas. He also makes a hard Alpine cheese in three varieties: plain, pepper or caraway. The milk is also bottled and sold frozen.

Health industry a big client

“Our main clients are health shops. The health and wellness industry is growing at a phenomenal rate, and goat’s milk fits right in,” explains François. “But the retail market is growing too, and some Spar supermarkets now stock some of our products.” The products’ biggest selling point is that they are suitable for people with lactose intolerance. However, such people can’t tolerate pasteurised goat’s milk, so Jean never pasteurises the milk unless it is used for cheese or yoghurt. “Our products also contain no preservatives, and the rennet used to make cheeses is not derived from animals, so the products are vegetarian,” explains Jean. Veld grazing is supplemented with urea-free Exel Nel 17 dairy pellets during milking, and supplementary lucerne in the evening.

Pleasant taste

But what about the pungent taste of goat’s milk? “Our milk doesn’t have a strong flavour and it tastes quite similar to cow’s milk,” says François. “The secret is to keep the bucks and does separate. The bucks urinate on their front legs to give themselves a strong scent. The females then breathe in the pungent odour which taints the milk.” François, who previously farmed with Santa Gertrudis cattle, tobacco and maize in Zimbabwe, manages the farming side of the business. Jean, who was in the interior decorating industry for 18 years, handles production. “Stephan was an excellent teacher,” he says, attributing much of their product Goat Peter’s success to him. “He is always willing to give us advice if we ask.”

François and Jean have 49 milking does, 30 young goats and two bucks. Many of the does are now pregnant, so they are starting to dry off and the twomonth quiet season is beginning. “Goats are also very seasonal – you can’t plan varied breeding seasons for them. But we believe nature must take its course so we don’t interfere,” says François. “We need to store frozen milk so that we have enough in the dry season to make our cheeses and other products.”

François has two bucks, Rufus and Brutus, bought from Fairview in Paarl. “It was a long way to go, but Fairview has good stock, and I wanted to make sure there’s no inbreeding.” François would like to import a buck, or possibly administer artificial insemination, from European stock.

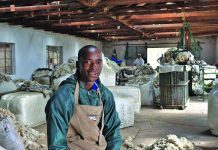

Milking and processing

Milking starts at 5:30am, with the goats coming into the parlour six at a time. While they are feeding, their udders are washed and checked and the milking machine is attached. It takes 15 minutes to milk six goats, because the milking machine only milks two at a time. From the milking machine, the milk is poured into a stainless steel bucket through a very fine honey sieve to catch any stray hairs. After weighing, it’s placed in a cooling tank, which cools to 5ºC. From the tank it is either bottled and frozen (Jean says frozen goat’s milk doesn’t go lumpy when thawed) or stored until there is enough to make cheese or yoghurt.

Every two to three days the collected milk is poured into the cheese vat where cultures and rennet are added. “We use different cultures to produce different varieties of cheese, sourced from a company called Lake Tech in Edenvale, which supplies large dairy producers,” explains Jean. The cheese is stored in a cold storage room and is matured for 10 to 14 weeks, before being vacuum-packed to keep it moist, as cheeses are not waxed. Besides a milk tank and cheese vat, François and Jean also have a pasteurising machine and a cheese-draining table to drain the whey. “I give this whey to a pig farmer nearby, and also add it to my compost because it’s rich in microbial activity,” says François.

Jean and François transport their products in cooler boxes in a van. “We’ll have to buy a refrigerated van when we expand,” says François. “We are just too small at the moment and we only just make a profit,” explains François. “So we don’t go out looking for new clients as we don’t yet produce enough to keep up with additional demand.”

Expansion plans

The first step is to milk the goats twice a day. “We will buy more goats as demand grows. Currently we milk 49 does, but we aim to have between 80 and 100,” says François. But there are challenges. “There are three or four other goat’s milk producers in Johannesburg, and two big ones – Fairview in Paarl and Mooiland in Free State – which are the main competition. But the real challenges we face are the input costs, especially feed and labour,” says François. “These prices have shot up lately. A one-litre plastic milk bottle with a lid costs more than R2,” he says.

Then there are power outages and a telephone land line that has been down since December. Jean often has to process cheese manually because there’s no electricity. But Jean and François remain optimistic. “It’s a really rewarding job. I see the whole process, and there is something tangible to show for your effort. And of course, it’s great to see our sales improving,” smiles Jean. Contact François on 083 279 5965 or Jean on 083 267 7457.

Goat’s milk ice cream

Danisco, one of the world’s leading producers of ingredients for food and other consumer products, has recently developed a new ice cream based on goat’s milk to target the growing demand for speciality products. According to analysts, the European ice cream sector has stagnated due to a maturation of the sector, health concerns and growing competition from cheaper private-label products. As a result, companies are moving into the market for more premium products and unusual combinations of flavours. Danisco says its goat’s milk ice cream is made with fresh, organic goat’s milk and is low in fat, but when combined with certain products, the ice cream achieves a “smooth and rich body”. It also claims that the vanilla flavouring used in the ice cream leaves room for a mild, tangy note of goat’s milk.

The product does not just offer a new taste – it has health benefits as well, claims the company. “Goat’s milk has a high level of medium-chain triglycerides and easily accessible proteins, making it more digestible than traditional cow’s milk. In addition, goat’s milk is claimed to contain more calcium, less lactose, less cholesterol and fewer allergens,” say Danisco.

Keeping goats healthy

Vet checks

François and Jean’s goats are an Onderstepoort herd, so all veterinary treatments are carried out by Onderstepoort. They do a full inspection of the herd four times a year, as well as checking the quality of the milk.

Pigmentation

The goats are Saanen goats from Switzerland, which are white. So lack of pigmentation, and the subsequent cancers, can be a problem in the harsh South African sun. François and Jean have therefore bought a few dark goats to introduce a darker pigment into the herd.

Deworming

François doesn’t blanket deworm his animals but uses researcher Dr Faffa Malan’s system which diagnoses the presence of parasites by the colour of the inside of the animal’s eyelid. “Then I can pick out specific animals that need deworming. The advantage of this is that the animals don’t work up a resistance to the deworming agent. I also don’t blanket dip for ticks. Because I see the goats in the parlour every day, I can see if ticks are getting out of control. Then I just use a paintbrush to paint tick deterrent on their fetlocks, because that’s where they get most of their ticks.”

Antibiotics

Some of François and Jean’s goats have a red stripe spray-painted on their rumps. “This marks the goats that are on antibiotics. Once they have finished their course of antibiotics we spray a green stripe over the red, so we know which animals we can milk,” explains François.

Hygiene

Particular attention is paid to hygiene on Sangwee farm. The goats are kept in shelters with grass bedding at night. These areas are cleaned twice a week and François uses the manure to fertilise his plants.

Beware of blended milk

A great threat to the goat’s milk market is the addition of cow’s milk, seemingly a relatively common phenomenon. Many products that are marketed as goat’s milk are in fact a blend of goat’s milk and cow’s milk. “Goat’s milk costs about five times as much as cow’s milk, and blending is an easy way to cut corners,” explains Jean. “It’s a big problem because it cancels out the benefits of goat’s milk. If a doctor tells a mother to feed her lactose-intolerant child goat’s milk, but the shop sells her a blend, she will see no improvement in the child’s condition, and will believe that goat’s milk is not a suitable alternative,” he says. “We bought some goat’s milk cheese to test the products that we compete with. The label said goat’s milk, but in the fine print the ingredients listed cow’s milk.”

Huge global demand, great land reform potential

The goat’s milk powder industry is one of the biggest agricultural value-adding businesses in the world, and South Africa is perfectly positioned to tap into this market, says respected Australian genetics expert and part-time milk goat farmer Alan Baron.

Due to its smaller molecule size and different protein structure, goat’s milk is more easily digested than cow’s milk, and may be the only milk tolerated by people with lactose intolerance, allergies or illnesses such as HIV/Aids and cancers of the stomach. “Baby formulas and all powdered milk products are very value-added because the cost of producing them is much lower than the selling price, and powdered goat’s milk in particular can be sold for a lot more than its cost of production,” says Baron.

New Zealand is the world leader in powdered goat’s milk products, with France also having huge goat dairies. But as first-world countries they face high labour costs. “This is where South Africa can benefit,” says Baron, especially when it comes to using land reform farms productively. An effective production chain can be formed, says Baron, where each link in the chain has a share in the business. “Goats can be housed densely, making it possible to have many goats on forced reclamation lands, with labourers doing the peripheral animal husbandry.

Big milking companies can then set up dairies and look after inputs like feed and machinery, with professionals to milk the goats.” Baron regards Limpopo as the ideal location. “We have land, we have firstworld management expertise and we have labour. All we need is the right breed of goat, but that can easily be taken care of, and within two or three years these goat farms can support dairies. As there is already a great demand for the product, the market has been taken care of. It’s truly an exciting possibility,” he enthuses.