They also dissipate heat from critical components, remove and suspend deposits that may affect performance, and act as a structural material. Lubricants extend the lifespan of large and small machinery and equipment and ensure production quality.

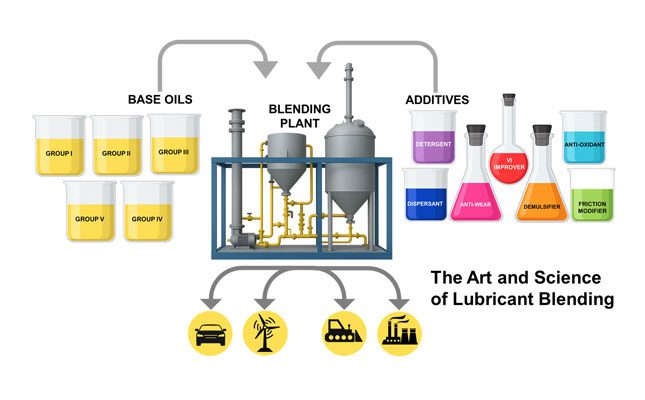

Lubricants are highly versatile with a range of applications from car engines and water pumps at nuclear power stations to bobbin cases of sewing machines, with each requiring a different combination of base oils and additives.

Formulating lubricants is a complex process that demands advanced engineering and chemistry expertise to create products that will perform effectively for the intended application. Conducted in specialised facilities called ‘lube kitchens’, this work requires an in-depth understanding of the chemical properties of each substance and how they will interact when combined.

Lubricant components

Base oils are the main component of lubricants, but additives are also needed to improve the good properties of the base oils and minimise the bad. Additives can be organic or inorganic compounds dissolved or suspended in the oil. While there are many lubricant additives available, they are selected based on the following:

- Suitability for the intended function

- Ability to mix easily with the selected base oils

- Compatibility with other additives in the formulation

- Cost-effectiveness

Typical lubricants are composed of a base oil, an additive package and, optionally, a viscosity index (VI) improver. Not all lubricants contain the same combination of additives and concentrations (called treat rates), which can range from 0.1% to 30% of the oil volume, depending on the application.

For example, turbine, hydraulic and industrial gear lubricants demand much lower ‘treat rates’ of additive packages compared to automotive gears, transmissions, and petrol and diesel engines, which are the most demanding and require the most additives.

Added to this, the geometry and metallurgy of the components, the operating temperatures, load, potential exposure to contaminants, combustion products, as well as typical drain intervals are also taken into consideration when selecting the ideal cocktail of additives for a specific application.

Ultimately the optimal combination of base oils and additives allows the finished lubricant to meet specified properties and performance characteristics outlined by Original Equipment Manufacturers and lubricant standards organisations.

For more info about the products, visit www.wearcheck.co.za.