When Raven Industries manufactured the first variable-rate control module for sprayers back in 1976, few could have predicted just how far precision technology would come.

Today, the company – founded in South Dakota, US, in the late 1960s – is central to the digital revolution in farming.

In 2021, Raven was acquired by global agricultural machinery giant CNH Industrial, parent company of New Holland and CASE IH.

Nico Myburgh, CNH’s head of precision technologies for the Middle East and Africa, says the acquisition enabled CNH to bring advanced connectivity and automation technologies in-house for integration into its own machinery and to provide aftermarket solutions to third-party manufacturers and retrofits.

“Having Raven under the CNH umbrella gives us full control of the value chain, allowing us to deliver smarter, more integrated systems from factory to field,” he explains.

Connected workflow

Raven’s expertise lies in application, machine control, and tractor guidance technologies.

Its systems are built on the ISOBUS standard, allowing universal compatibility between implements and tractors and across platforms.

At the core of the ecosystem is Slingshot®, a cloud-based platform where machine and field data are collected, stored, and managed.

Slingshot lets farmers pre-plan and create work orders in real time, including product mixes, prescription maps for variable-rate applications, nozzle configurations, field boundaries, and GPS guidance for field operators.

Because all connected machines are synced to the platform, multiple units working on the same job can see each other’s progress in real time and pick up exactly where the other has left off.

According to Myburgh, the solution improves efficiencies by enabling variable-rate applications and eliminating overlaps and missed patches when multiple machines are used.

Additionally, Slingshot enables real-time machine monitoring, allowing farmers to track productivity, spot issues early, and provide remote support and updates.

All the data are stored in the cloud, enabling season-to-season benchmarking and allowing farmers to make better-informed decisions when planting as well as applying fertiliser and herbicides.

Rate control

In terms of machine control, Raven’s Rate Control Module (RCM) uses algorithms to improve seed, fertiliser, and crop protection application across a wide range of implements.

Myburgh says the RCM is like “brains behind every precision pass”: in less than a second, it receives sensor data, calculates optimal application rates, and sends signals valves, motors, and actuators to apply seeds or chemicals accurately.

The RCM is modular, portable, and universal, so it can be moved between machines or implements and can manage multiple products and sections simultaneously. For instance, it can control several tanks and multiple boom sections on a sprayer.

It also has plug-in architecture, allowing farmers to use modular plug-ins to adapt to a wide range of applications, instead of needing different controllers for each job.

These plug-ins cover everything from product and section control to blockage detection and tank levels.

Nozzle control

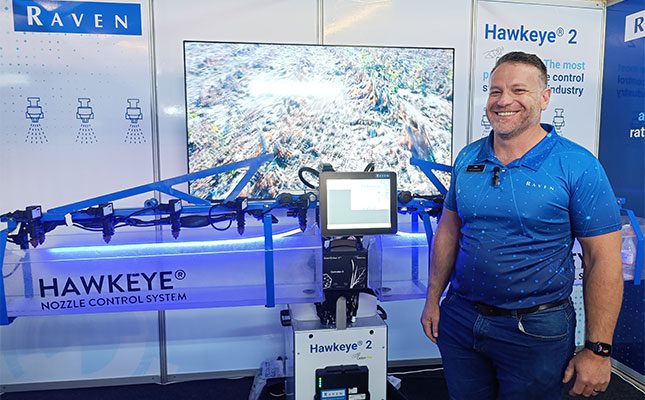

Raven’s HawkEye®2 Nozzle Control System brings physical precision to spraying, as it features individual on and off nozzle control valves that dynamically adjust each spray point in real time in response to changes in speed, wind terrain, and turning radius.

Myburgh says this highly advanced system ensures every part of the field receives the correct dosage of fertiliser, pesticide, herbicide, or foliar feed, translating into lower chemical costs, improved yields, and reduced drift.

According to Raven’s product information, HawkEye 2 always delivers applications within 5% of the target rate, even in tough conditions; is 250% more accurate than competitors’ nozzle control systems; and can control up to 192 individual nozzles.

It includes advanced blockage detection, alerting operators in real time when a nozzle is clogged or underperforming.

Vision tools

Precision spraying is taken to the next level through seamless integration with various vision tools.

Carbon Bee, for instance, is mounted directly onto a sprayer boom close to nozzles. It uses a high-resolution camera and vision system with machine learning (ML) and image processing to distinguish between weeds and healthy and sick plants at the canopy level, as a sprayer moves through a field.

Thus, it enables ultra-localised spray decisions, such as the spot spraying of sick plants or weeds.

While Carbon Bee focuses on plant-level decisions from the boom, Augmenta® Field Analyzer scans broad zones from the roof of a tractor or sprayer cab.

Augmenta uses multispectral cameras, ML and artificial intelligence to provide agronomic insights based on crop health indicators, such as biomass and chlorophyll levels.

The results guide real-time application and optimise input use for everything from nitrogen to harvest aids.

Myburgh says the advantage of using these sensor technologies is that farmers can respond to what is happening in their fields in real time, rather than waiting for drone or satellite images to guide applications. They also deliver significant savings compared with blanket applications, where the entire field is treated.

Machine monitoring

Beyond advanced spraying and data tools, Raven’s tractor guidance technologies enable accurate, automated steering for tractors, sprayers and other field equipment.

“Raven’s guidance tools lay the foundation for everything else. If you cannot stay on the line, you cannot do precision planting, spraying, or fertilisation,” says Myburgh.

Precision fertilisation places nutrients at the exact position and depth in a row before seeds are planted, ensuring they can access nutrients efficiently and reducing wastage.

The RS1™ GPS unit serves as an all-in-one autosteer controller, combining a GPS receiver, steering controller, and cellular modem for connectivity and over-the-air updates. It processes GPS signals, calculates the tractor’s position, and sends commands to the steering system, called DirectSteer™, to keep the tractor on the correct path.

DirectSteer provides precise, responsive steering control, directly interfacing with the tractor’s hydraulics.

Fleet management

Raven Connected is built into the Slingshot platform and allows farmers to optimise machine operations by offering real-time tracking, maintenance scheduling, fuel consumption, route optimisation, and driver performance monitoring. Farmers can also access historical data.

Myburgh adds that New Holland and Case IH monitor the performance of machines remotely, with the machines switching off completely if there is a critical fault or driving slower when the fault is not as severe.

“Operators can speak to the service provider to fix faults remotely, such as a blocked nozzle or faulty sensor,” he explains.

“If the fault cannot be fixed remotely, then the service provider will have a good idea of the location of the problem and the parts that might be needed to fix it.”

With technologies like these becoming more accessible, Myburgh adds that Raven is helping South African farmers optimise production, improve efficiencies, reduce costs, and become more environmentally responsible.

Fore more information email Nico Myburgh at [email protected].

Get trusted farming news from Farmers Weekly in Google Top Stories.

➕ Add Farmers Weekly to Google ✔ Takes 10 seconds · ✔ Remove anytime