The quality of livestock feed significantly influences the overall health of animals. High-quality feed should therefore include a balanced mix of nutrients from highly digestible ingredients while also being safe to consume. It should support optimal growth and physiological functioning, reproduction, and overall health.

In contrast, poor-quality feed can lead to nutrient deficiencies and introduce harmful contaminants like pathogens, mycotoxins, toxins, and chemical residues that can negatively impact livestock.Preventing and controlling feed-borne pathogens is vital for the health and productivity of livestock owners’ production systems.

Feed contamination and recontamination can occur at any step within the feed supply chain, from the sourcing of raw materials to the storage and transportation of finished feeds. Since contaminants can compromise animal health, feed manufacturers employ comprehensive strategies to mitigate risks in this regard.

“As the representative body of South Africa’s animal feed industry, the Animal Feed Manufacturers’ Association [AFMA] enforces a self-regulatory code of conduct that upholds feed safety, quality assurance, and best practices in feed production,” explains Petru Fourie, operations manager at AFMA.

Raw materials

According to Marzanne Cromhout, technical manager at Rossgro Feeds, raw materials are broadly classified into macro- and micro-ingredients.

“Macro raw materials typically include maize, wheaten bran, gluten, full-fat soya, and oilcake. These ingredients form the bulk of the formulation and are essential for providing energy, protein, and fibre. They can be sourced either directly from farmers or through commodity traders, depending on availability, pricing, and supply chain logistics,” she explains.

Cromhout points out that micro-ingredients include products like limestone, amino acids, vitamins, minerals, enzymes, and other feed additives.

“Although these components are used in smaller quantities, they play a crucial role in meeting the specific nutritional and physiological needs of the animal. Micro-ingredients are typically premixed into vitamin-mineral premixes to ensure proper distribution in feed.

These products are typically imported by various companies, and there are numerous variations and formulations of each available in the market,” she explains.

Cromhout adds that the selection of specific products is determined by a company’s nutritionist, who bases the decision on the animal’s nutritional requirements, scientific research, and technical data, as well as the proven efficacy of the product through validated trials and performance results.

Tanel Meyer, technical specialist at Chemuniqué, stresses that when procuring raw materials, it is vital to understand the suitability of ingredients for the specific species’ diet, as well as the type of diets within species, such as layers versus broilers.

In addition, Meyer points out that the type of grain used in a feed is determined by its nutrient composition.

“Maize, for example, is a great source of energy in livestock feed, whereas wheaten bran contributes a greater portion of fibre to the feed. Grain quality is impacted by its moisture content, as higher moisture levels promote mould growth and potentially an increased risk of mycotoxin contamination. Grain should also be free of foreign materials, including stones, dirt, and weed seeds,” she says.

Meyer emphasises that it is important to source raw materials from reputable suppliers who comply with government regulations and follow industry standards, providing a product that conforms to the expected nutrient level of the specific ingredient.

“This includes, but is not limited to, nutrients such as moisture content, crude protein, fibre, and ash,” she says.

According to her, when purchasing large-volume products like grain, the availability of the product will impact the usage and inclusion in formulations and by-products.

“It is important to always have enough stock to avoid any unnecessary variation in diet composition and costly reformulations.”

Meyer says using enzymes in livestock feed is a tool to help enhance nutrient utilisation and feed efficiency, reduce feed costs, and minimise environmental waste.

“Adding enzymes to a diet is, however, animal- and substrate-specific. Using a phytase in feed to release phytic-bound phosphorus is mainly applied in monogastric animals, who lack a sufficient amount of endogenous phytase to break down phytic acid,” she explains.

She adds that enzymes play a key role in unlocking certain nutrients that would otherwise have been unavailable to animals and would potentially have been excreted.

“When choosing an enzyme supplier, make sure that its claims can be backed by peer-reviewed science. It is even better if the product has been validated with proven efficacy in South Africa, using local ingredients.”

Packaging and delivery formats

Macro raw materials are typically delivered in bulk, usually in quantities of around 30t, to accommodate the large volume requirements of feed production.

In contrast, micro-ingredients are supplied in 1t bulk bags or smaller 20kg bags, depending on the nature of the product and handling requirements.

The packaging format is often determined by what the feed mill requires and is equipped to handle, ensuring efficient storage, handling, and incorporation into the feed-manufacturing process.

Feed formulas

With regard to specific feed formulas, Cromhout explains that the formulation process involves aligning the nutrient requirements of the animal with its physiological and production goals. This ensures optimal health, performance, and feed efficiency.

According to Dr Naudé Rossouw, director at Rossgro Feeds, feed formulations are designed based on:

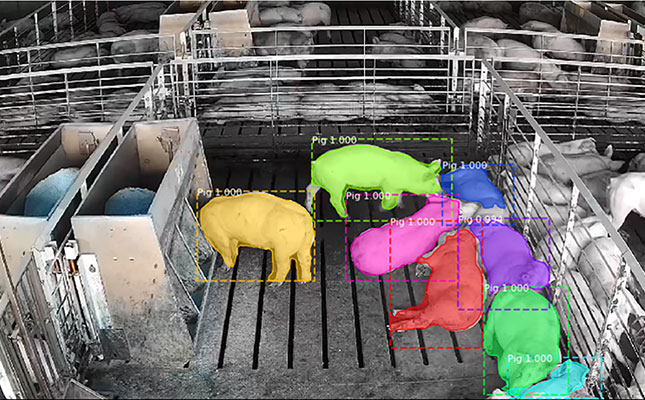

- The type of animal, for example, poultry, cattle, sheep, or swine;

- Their production status, such as growth phase, lactation, or reproduction; and

- The desired product, such as small or jumbo eggs, or 1,8kg broilers every four to six weeks.

Feed quality is the primary driver of feed intake and animal productivity. The quality of the feed on offer also determines the type and amount of supplements required.

Meyer adds that formulations are determined by the species (such as ruminant or poultry), the class of farm feed (for instance, dairy versus feedlot), and will also take age, production level, and type of feed (concentrate versus complete feed) into consideration.

There is a fine balance between the nutritional requirements of the target animal in relation to the target production.

“Diets also vary depending on the intensity of the farming operation. For optimal production, our rations need to be formulated by a qualified and registered animal nutritionist, as employed by Rossgro Feeds,” explains Rossouw.

While nutritional standards and research data provide the foundation, Cromhout points out that the final formulation may be adjusted by the nutritionist based on practical experience, raw material availability and quality, local production conditions, and goals.

The technical team at Rossgro plays a critical and central role in the operations of the feed mill.

“This is also true for most other feed manufacturers. The technical team normally consists of the technical manager, nutritionist or formulator, a procurement officer, and a quality or laboratory manager. Their responsibilities go far beyond simply selecting ingredients. They are directly responsible for ensuring that the feed produced is nutritionally balanced, cost-effective, and aligned with production goals,” says Cromhout.

“Without a competent technical team, a feed mill risks producing feed that is either nutritionally inadequate, too expensive, or non-compliant, all of which can lead to poor animal performance, economic losses, or legal issues.”

According to Cromhout, a typical breakdown of such a team’s role includes:

- The least-cost formulation of balanced diets: the nutritionist ensures that each feed formulation provides the optimal levels of energy, protein, fibre, vitamins, and minerals required for the specific animal species and its production stage, such as growth, lactation or finishing.

The formulation directly affects the animal’s health and welfare, growth performance, reproductive efficiency, and product (meat, milk, eggs) quality.

- Cost optimisation: feed typically accounts for 60% to 70% of the total cost in animal production. A skilled nutritionist is able to optimise formulations to minimise cost while maintaining nutritional quality and adjust formulas based on fluctuating raw material prices and availability, while using least-cost formulation software, and other tools to achieve cost-efficiency and maintaining nutritional standards.

- Ingredient selection and evaluation: the technical manager will evaluate the quality of raw materials from different suppliers and make decisions about which additives or enzymes to include based on scientific research and field performance.

It is also important to respond to changes in raw material nutrient composition, which can vary due to origin, season, or processing. Procurement will then ensure the products are purchased and delivered;

- Complying with regulations: the formulation of animal feed is regulated by the Fertilizers, Farm Feeds, Agricultural Remedies and Stock Remedies Act (No. 36 of 1947).

Cromhout says technical managers will typically ensure that feed formulations comply with local and international regulations on feed safety and nutrient levels, as well as withdrawal periods for certain additives.

“Quality-assurance protocols are put in place to prevent contamination and nutrient imbalances,” she says.

According to Liesl Breytenbach, executive director at AFMA, the association audits its members every two years through an independent body to verify code of conduct compliance.

“Only compliant members may use the AFMA Code of Conduct logo, issued upon passing the audit, a mark of commitment to feed and food safety,” she says;

- Technical support and continuous improvement: the technical team works with the nutritionist and the production staff to troubleshoot issues.

“There is also direct interaction with clients/customers to ensure optimal production on farm level. It is important to conduct and interpret feed trials and performance data. The team members support each other to ensure they stay updated with new research, technologies, and regulations,” explains Cromhout.

The role of the nutritionist

In accordance with Act No. 36 of 1947 (the Act), all registered animal feeds must be formulated by a registered professional from the South African Council for Natural Scientific Professions (SACNASP),” explains Breytenbach.

“AFMA fully supports this regulation, as it promotes scientific accountability, nutritional safety, and professional oversight.”

Meyer confirms that a SACNASP-registered nutritionist is required to sign off on any formulations submitted for registration to the registrar of the Act and has to specify the nutrient profile of the feed.

“However, the nutritionist is responsible for using the appropriate raw materials or ingredients to reach these nutrient targets and has to ensure that it is safe for animal consumption.”

She explains that the on-site nutritionist would be responsible for the quality control of raw materials that are chosen to be included in the feed mixtures.

“The responsibility would include quality reports for every incoming load of raw materials and to report any non-conforming raw materials.”

Meyer points out that once feed manufacturing starts, quality is continuously monitored throughout the process.

“Proximate analysis can be done to measure inter alia moisture, crude protein, fat, and fibre, and ash. Near-infrared spectroscopy is most commonly used in feed mills to determine these proximates.”

Final product

After the feed is manufactured, it must be delivered on-farm. According to Meyer, the packaging of the product will impact its shelf life, thus it is necessary to choose and use appropriate packaging for each type of product.

“It is also important to remember that shelf life will differ between the various feed types. In addition, the level of exposure to moisture and ultraviolet light will also have an impact. Your packaging choice should consider the type of feed, scale of distribution (bags versus bulk), storage conditions, and target customers, for example commercial farmers versus smallholders.”

Meyer states that packaging should allow for the appropriate labelling of the product, and that it must be visible and applied in accordance with regulations set out in the Act.

“The label should contain the following: product name; manufacturer information; V-registration number; nutritional analysis, including moisture, crude protein, fibre, and so on; as well as the batch number and expiry date,” she explains.

Breytenbach adds that clear, compliant labelling, including any product warnings where applicable, builds trust and ensures traceability in line with AFMA’s Code of Conduct and the Consumer Protection Act (No. 68 of 2008).

According to Meyer, the form of feed largely depends on the species, nutrient density of the diet, and consumer need. She explains that pelleting of broiler feed improves feed intake and reduces wastage, whereas pelleting of layer feed would be impractical due to the inclusion of high volumes of coarse limestone.

Feed can be supplied in two main formats – bulk or bagged – depending on the size and infrastructure of the farming operation.

- Bulk feed

Cromhout mentions that bulk feed is delivered in tankers with capacities of 12t, 24t, or 30t, and is typically used by larger farms equipped with on-site feed silos.

“This method offers several advantages, including improved handling efficiency, reduced packaging waste, lower logistics and handling costs, as well as easier inventory management for both sides – the manufacturer as well as the farmer. Bulk delivery is often more cost-effective and logistically efficient for commercial-scale operations,” she says.

- Bagged feed

Bagged feed is commonly used by small to medium-sized farms or in markets with limited storage infrastructure. Packaging sizes typically range from 2kg to 50kg, depending on market requirements, distribution channels, farm size, and feeding systems.

This format offers greater flexibility for manual handling and small-batch feeding, especially in rural or remote areas.

Feed mills can produce feed in different physical forms, depending on the nutritional needs, feeding behaviour, and digestive capacity of the target animal.

The type of feed form selected is based on the species, age, and production stage of the animal, as well as the feeding system used on the farm. The three most common types are mash, pelleted, and crumb feed.

- Mash feed

Mash feed is finely ground, loose, and unprocessed feed typically used for laying hens, pigs, and sometimes ruminants. According to Cromhout, these are easy to manufacture and allow for uniform mixing of micro-ingredients. - Pelleted feed

Pellets are compressed, cylindrical feed particles formed through steam conditioning and pelleting, and used for broilers, pigs, and cattle.

“Pellets improve feed efficiency and intake and reduce feed wastage and selective feeding,” says Cromhout.

According to Meyer, pelleting also positively impacts factors like dust exposure.

- Crumb feed

Crumb feed comprises crushed pellets, resulting in smaller, coarse particles used for young animals, such as chicks and piglets. Cromhout says it is easier for young animals to consume crumb feed, which maintains the nutritional value and benefits of pelleted feed.

Standards

Focusing on standards, Cromhout states that the animal feed mill industry is obliged to manufacture a feed that is as homogenous as possible to ensure consistent nutrient intake and optimal feed conversion efficiency.

“It is important that every animal should receive all nutrients and active substances as prescribed in the formulation in sufficient quantity and of correct quality daily.

“There are four fundamental aspects of feed quality that must be carefully managed throughout the manufacturing process. Each aspect involves the collaboration of specialised teams to ensure that the final product delivers the intended nutritional and economic value.”

Cromhout points out the following important aspects:

- Physical properties of ingredients

The technical, procurement and production teams at the manufacturer are normally responsible for ensuring that products adhere to the necessary standards.

“The procurement team plays a key role in sourcing materials that meet technical specifications and processing requirements,” she stresses.

Physical traits like particle size, texture, and bulk density affect both processing and feed intake. In addition, the proper handling, grinding, and raw material selection ensure smooth flow, better mixing, and improved pellet quality.

- Nutrient content and balance

The responsible team, including nutritionists, a formulator and technical manager, ensures that feed formulations meet performance targets while also optimising cost and ingredient availability.

“Feed must provide the exact balance of energy, protein, fibre, vitamins, and minerals required for each species and growth stage. Variability in raw material nutrient composition demands ongoing formulation adjustments and frequent laboratory analysis,” says Cromhout.

- Homogeneity of mixing

The feed mill production team, with the technical manager and the quality control team, must ensure homogeneity.

“The uniform distribution of all feed components, especially micro-ingredients like vitamins, minerals, and additives, is critical. The production team ensures consistent mixing times, proper mixer load capacities, and well-maintained equipment,” explains Cromhout.

She adds that inadequate mixing can lead to nutrient segregation, resulting in performance loss and health issues in animals.

Animal and human safety

Quality control, the technical manager, and housekeeping hold primary responsibility for animal and human safety.

“Feed must be free from contaminants like mycotoxins, pathogens, heavy metals, and chemical residues. Quality-control ensures rigorous testing of raw materials and finished products. In addition, good housekeeping practices prevent cross-contamination,

spoilage, and infestation, ensuring feed is safe for consumption and compliant with food safety standards,” explains Cromhout.

“High-quality feed is the result of a well-coordinated effort across multiple departments. From sourcing and formulation to production and quality assurance, each team plays a vital role in maintaining the integrity, safety, and performance of the feed. Only by taking all the aspects into account can a feed mill deliver a consistent, effective, and safe product to the livestock industry.”

Rossgro Feeds has its own laboratory that has been put in place to ensure raw materials received as well as finished products meet the necessary requirements, says Rossouw.

“Certain crops are more prone than others to mycotoxin contamination; this risk is managed by sending samples to an external laboratory as required.”

He also points out that Rossgro Feeds follows good manufacturing practices, as prescribed by AFMA, to ensure that safety regulations and the correct work procedures are followed.

For more information email Marzanne Cromhout at [email protected], Tanel Meyer at [email protected], and Liesl Breytenbach at [email protected].